Email Id: sale@adctooling.com

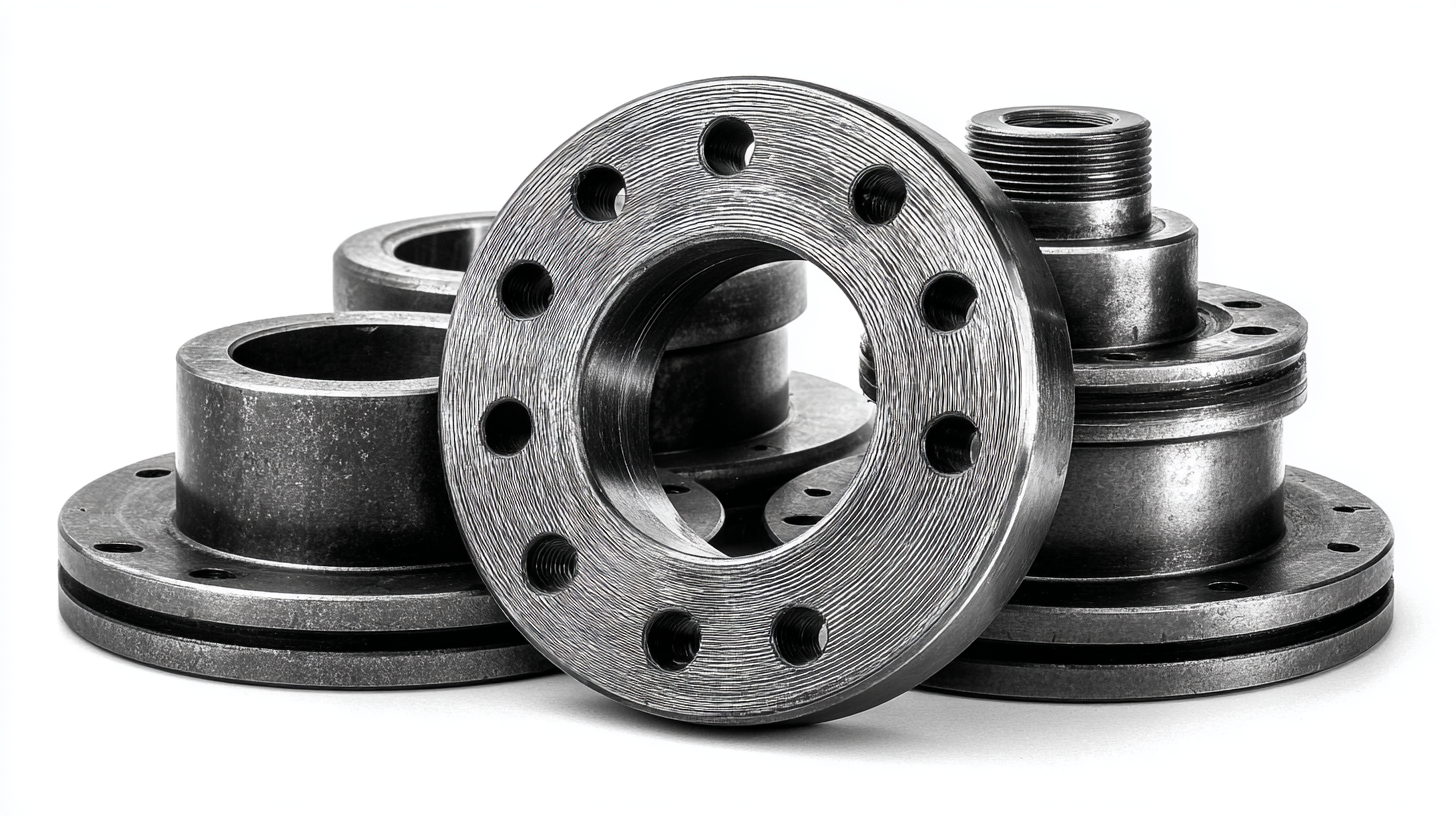

In the world of industrial piping systems, understanding the various types of pipe flanges is crucial for buyers seeking to make informed decisions. Pipe flanges serve as essential components that facilitate the connection between sections of pipe, allowing for seamless transportation of fluids and gases. With an array of styles, materials, and standards available, navigating the complexities of pipe flanges can be daunting for even the most seasoned professionals. This comprehensive guide aims to shed light on the different types of pipe flanges, their specific applications, and key considerations for global buyers.

By delving into the unique characteristics and functionalities of each flange type, readers will be better equipped to select the right flange that meets their specific requirements, ensuring safety, durability, and efficiency in their piping systems.

When it comes to pipe flanges, understanding the various types is crucial for global buyers seeking efficiency and reliability in their projects. Among the most common variants are the weld neck, slip-on, and blind flanges, each serving distinct purposes in piping systems. According to a report by MarketsandMarkets, the global flange market is anticipated to reach USD 8.0 billion by 2025, driven by increasing demand across industries such as oil and gas, chemicals, and construction.

Weld neck flanges are characterized by their tapered necks, allowing for robust welding to the pipe. This makes them particularly suitable for high-pressure applications. In contrast, slip-on flanges are easier to install, as they simply slide over the pipe's end before being welded in place, making them a cost-effective choice for many applications. Lastly, blind flanges, which do not have a bore, are essential for closing off pipelines in maintenance or testing scenarios, reflecting the need for versatile sealing solutions in various industrial setups. Each type of flange significantly contributes to the safety and efficiency of fluid transport systems, underlining their importance in the global market.

| Flange Type | Description | Material | Common Applications |

|---|---|---|---|

| Weld Neck Flange | Designed for high-pressure applications with a tapered neck. | Stainless Steel, Carbon Steel | Oil and Gas, Chemical Processing |

| Slip-On Flange | Slides over the pipe and is welded in place, suitable for lower pressure. | Carbon Steel, Alloy Steel | Water Supply, HVAC Systems |

| Blind Flange | Used to close the end of a piping system. | Stainless Steel, Carbon Steel | Waterworks, Piping Systems |

| Socket Weld Flange | Designed for high-pressure pipe connections, the pipe fits into a socket. | Stainless Steel, Carbon Steel | High Pressure Applications, Gas Transmission |

| Threaded Flange | Features internal threads to attach to corresponding pipes; no welding needed. | Carbon Steel, Stainless Steel | Low Pressure Applications, Systems Requiring Frequent Disassembly |

When it comes to piping systems, flanges play a crucial role in ensuring connectivity and integrity. Understanding the functions and applications of different flange types can significantly impact the efficiency and safety of industrial processes. Flanges serve as the interface for connecting pipes, valves, pumps, and other equipment, acting as a barrier against leaks while accommodating thermal expansion and compression. The most common types of flanges include weld neck, blind, and slip-on flanges, each offering unique advantages tailored to specific applications.

Weld neck flanges, for instance, are designed for heavy-duty applications where robust strength is necessary. They provide a gradual transition in diameter that reduces stress concentrations at the joint, making them ideal for high-pressure systems. Conversely, blind flanges are used to seal the ends of piping systems to prevent fluid flow, making them a vital component in maintenance and testing scenarios. Slip-on flanges, known for their ease of installation, are commonly utilized in low-pressure applications, allowing for quick assembly while maintaining a secure connection. By understanding these variations and their respective uses, global buyers can make informed decisions that enhance their piping system designs.

When selecting the right pipe flange, material consideration is paramount. Flanges are available in various materials, each with unique properties that can significantly impact their performance in different environments. Common materials include carbon steel, stainless steel, and plastic, each offering distinct advantages. For instance, carbon steel flanges are known for their strength and durability, making them ideal for high-pressure applications. Conversely, stainless steel flanges resist corrosion, making them suitable for environments exposed to moisture or chemicals.

Aside from the basic material types, buyers should also consider factors such as temperature and pressure ratings. High-temperature applications may require flanges made from specific alloys to prevent deformation, while higher pressure demands manufacturing techniques that can withstand intense forces. Additionally, environmental conditions, such as exposure to aggressive substances or extreme temperatures, will dictate the choice of material. By understanding these material considerations, buyers can ensure they select the right flange that meets both the operational requirements and longevity needed for their projects.

When it comes to flange assembly, understanding the proper installation techniques is crucial for ensuring the integrity and performance of various mechanical systems. One of the key areas to focus on is flange runout, which can significantly affect the quality of the installation. A recent overview highlighted best practices for measuring flange runout, emphasizing the importance of utilizing a precise number of lug nuts. Depending on the specific requirements of the installation, using either two or five lug nuts can yield the most accurate results, ultimately leading to a well-balanced assembly and optimal function.

Furthermore, adept installation isn't just about the number of lug nuts; it also requires a deep understanding of the unique characteristics of different flanges and assemblies. For instance, the choice of materials and the application of proper torque can vary. Following guidelines for liquid flashing installation showcases how precision and technique are critical in achieving a reliable seal, much like in flange assembly. By adhering to best practices and recommendations from industry experts, buyers and installers can enhance their understanding of flange systems, ensuring durability and efficiency in their operations.

When navigating the complex world of pipe flanges, understanding global standards and classifications is essential for buyers. Flanges are categorized primarily according to their design and application, with the most common classifications being weld neck, slip-on, blind, and threaded types. Each type serves a distinct purpose, determined by factors such as pressure requirements, piping configurations, and material compatibility. Familiarity with these classifications not only aids in selecting the appropriate flange but also ensures compliance with international safety standards.

Globally recognized standards such as ASME, ANSI, and API provide a framework for flange design and manufacturing, ensuring consistency and reliability across different regions. For example, ASME B16.5 specifies the dimensions and tolerances for flanges used in piping systems, while ANSI outlines the pressure-temperature ratings. These standards facilitate interoperability between components from different manufacturers, minimizing compatibility issues in global supply chains. By understanding these classifications and standards, buyers can make informed decisions that enhance project efficiency and safety.