Email Id: sale@adctooling.com

As the industrial sector continues to evolve, the demand for high-performance materials such as PTFE lined pipe has seen significant growth, driven by its exceptional chemical resistance and durability. According to a recent market analysis by MarketsandMarkets, the global PTFE market is projected to reach USD 2.6 billion by 2025, reflecting an increasing need for innovative piping solutions in diverse applications, including chemical processing and pharmaceuticals.

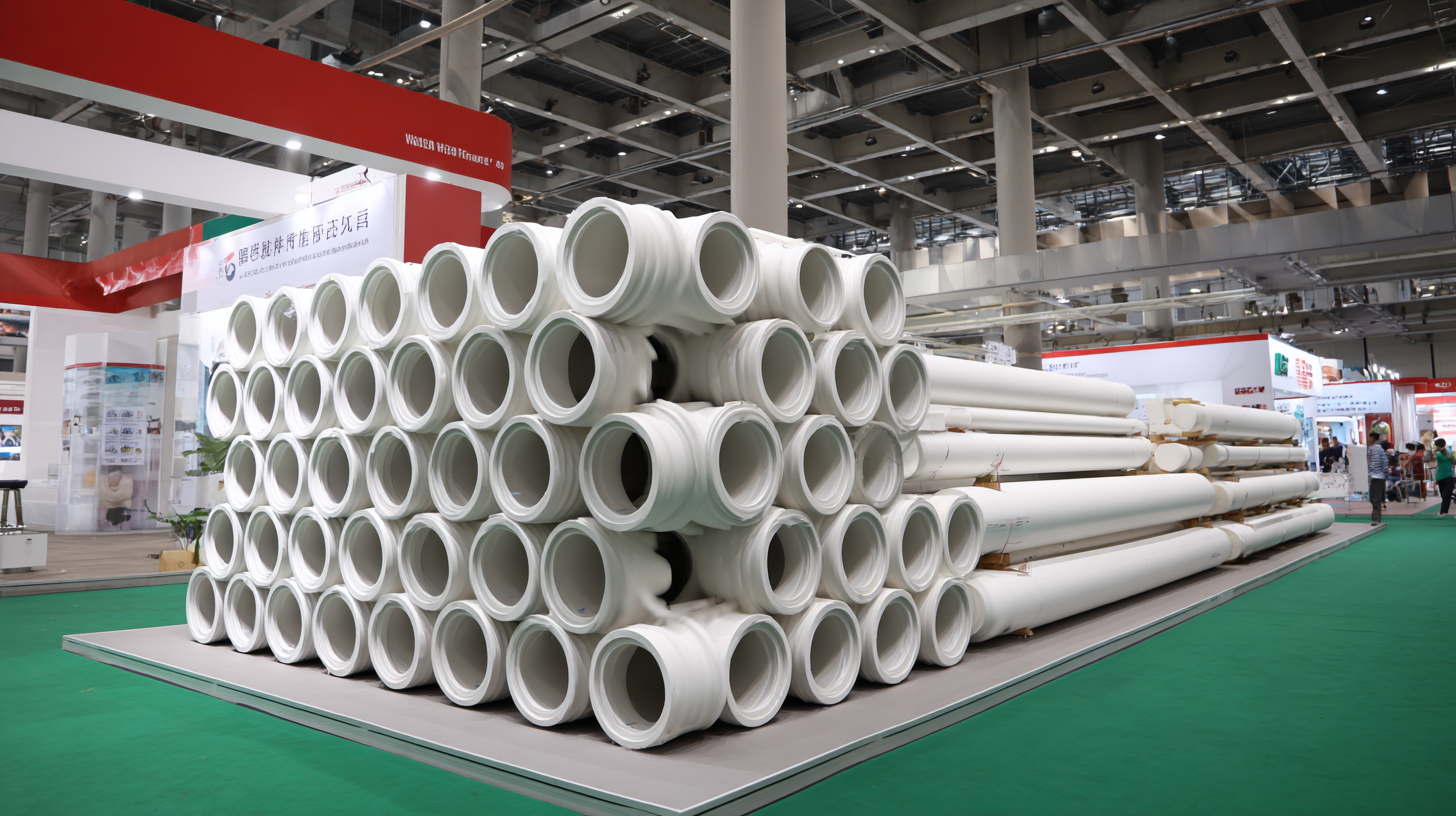

The upcoming 2025 China 138th Canton Fair promises to showcase cutting-edge advancements in PTFE lined pipe technology, attracting industry leaders and manufacturers committed to enhancing fluid handling systems. With China's rapidly expanding industrial landscape, the fair presents an invaluable opportunity to explore the latest innovations in this critical sector, addressing the urgent need for reliable and efficient piping solutions that meet stringent industry standards.

At the 2025 China 138th Canton Fair, innovations in PTFE lined pipes are anticipated to steal the spotlight across various sectors. These pipes, renowned for their remarkable chemical resistance and temperature stability, have been making waves in industries ranging from pharmaceuticals to food processing. According to a recent report by the Global PTFE Lined Pipe Market, the sector is expected to grow at a CAGR of 7.5% from 2022 to 2030, reflecting an increasing demand for reliable piping solutions in harsh environments.

Vulnerable to corrosion and extreme conditions, traditional piping systems often fall short. This is where PTFE lined pipes excel, offering unparalleled performance for transporting aggressive chemicals and high-purity materials. In the pharmaceutical industry, for instance, these pipes ensure that the integrity of sensitive substances is preserved, adhering to stringent safety regulations. Similarly, in the food processing sector, PTFE linings prevent contamination and maintain the quality of consumables.

Tips: When considering PTFE lined pipes for your application, evaluate the chemical compatibility of the lining material with your substances to ensure longevity and performance. Additionally, assess the temperature and pressure ratings to guarantee optimal functionality in your specific environment. By making informed choices, industries can enhance their efficiency and reduce maintenance costs significantly.

The advancements in PTFE lined pipe manufacturing technologies are set to be a focal point at the 2025 China 138th Canton Fair. As industries increasingly require corrosion-resistant solutions, the demand for PTFE (Polytetrafluoroethylene) lined pipes has surged, leading to significant innovations in their manufacturing processes. According to a recent industry report by MarketsandMarkets, the global market for PTFE lined pipes is projected to grow at a CAGR of 6.3% between 2023 and 2028, driven by heightened usage in sectors such as chemical processing, pharmaceuticals, and food production.

At the Canton Fair, manufacturers are expected to showcase cutting-edge technologies that enhance the efficiency and durability of PTFE lined pipes. Innovations such as advanced extrusion methods and automated lining processes not only reduce lead times but also improve the uniformity and integrity of the linings.

This technological evolution is crucial, especially as the performance of lined pipes directly influences the safety and efficiency of fluid transfer in industrial applications. The integration of smart materials and IoT connectivity into piping solutions further exemplifies the shift towards more sophisticated, reliable systems that can monitor performance in real-time, thereby optimizing maintenance schedules and reducing operational costs.

The upcoming 2025 China 138th Canton Fair presents an excellent opportunity to explore the latest innovations in PTFE lined pipes, which are increasingly recognized for their environmental benefits in industrial settings. Made from polytetrafluoroethylene (PTFE), these pipes are resistant to corrosion and chemical reactions, making them ideal for transporting hazardous materials without contributing to environmental pollution. Their longevity and durability also mean fewer replacements and less waste, aligning with sustainable industrial practices.

Implementing PTFE lined pipes can significantly reduce the environmental impact of industrial operations. Their smooth inner surface minimizes friction, leading to energy savings through reduced pump energy requirements. This efficiency not only lowers operational costs but also curtails carbon emissions associated with energy production.

**Tip:** When evaluating PTFE lined pipe options, consider the specific chemical compatibility and temperature requirements of your application. This will ensure optimal performance and safety.

**Tip:** Thoroughly inspect and maintain your PTFE lined pipes regularly to prevent leaks, further enhancing their environmental benefits and ensuring compliance with regulatory standards.

The 2025 China 138th Canton Fair promises to be a pivotal event for the PTFE industry, showcasing a range of innovative products and technologies. Key exhibitors will present cutting-edge PTFE lined pipes that enhance durability and performance across various applications. From chemical processing to food production, the advancements in PTFE lining aim to address common challenges such as corrosion resistance and thermal stability, making these pipes indispensable in demanding environments.

Among the standout exhibitors, several companies are anticipated to unveil their latest PTFE innovations. Leading manufacturers will demonstrate enhanced techniques for lining pipes, ensuring seamless integration and improved efficacy. Additionally, products featuring proprietary coatings and seamless connections will offer attendees insights into the future of fluid handling solutions. Visitors can expect live demonstrations and expert discussions, fostering an environment of collaboration and knowledge exchange in the field of PTFE technology.

The demand for PTFE lined pipes is witnessing a significant surge, driven by their exceptional performance in corrosive environments across various industries. According to a recent report by MarketsandMarkets, the global PTFE market is projected to reach $3.04 billion by 2026, growing at a CAGR of 5.9%. This forecast highlights the increasing preference for PTFE solutions in sectors such as chemicals, pharmaceuticals, and food processing, where reliability and safety are paramount. Innovations showcased at the 2025 China 138th Canton Fair will reflect these trends, as manufacturers push the boundaries of PTFE technology to enhance durability and efficiency.

Future trends indicate a shift toward more sustainable and eco-friendly PTFE solutions, in line with global sustainability goals. The International Association of Plastics Manufacturers released data underscoring that the adoption of advanced PTFE compounds can reduce energy consumption in manufacturing processes by up to 20%. Additionally, the integration of smart technologies within PTFE lined systems is expected to optimize operational efficiency, allowing for real-time monitoring of fluid dynamics. As the market evolves, the focus will likely remain on enhancing performance while minimizing environmental impact, setting a new standard for pipeline solutions in the industry.